Almost 30 years all kinds of concrete block molds manufacturing experience;

80000 or 120000 cycle times for choice;hardness reach 62 degree after heat treatment.

Order(MOQ) :

1 SetPayment :

T/T 100% payment before shipment or 100% by confirmed, irrevocable L/C at sight.Product Origin :

Quanzhou FujianColor :

customize to demandShipping Port :

XiamenLead Time :

20-25 daysMASA HESS Hollow Interlocking Concrete Block Molds for concrete brick factory:

Brief introduction:

The material of the mold is alloy steel, and the material of the wearable parts is wear-resistant material. After heat treatment, the wear resistance of the wear-resistant material is the best, and the processing technology is constantly improved, so that the mold produced by our company on the market can achieve a good use effect.

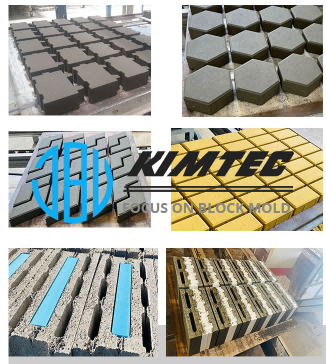

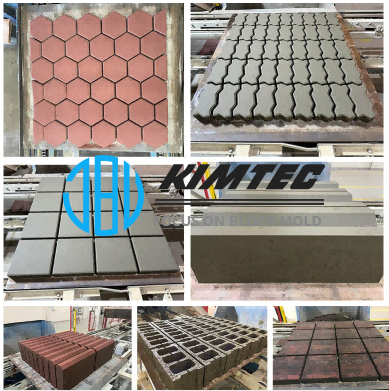

At present, our factory mainly produces road bricks, hollow bricks, square bricks, grass bricks and other brick moulds.

Our moulds are suitable for almost all kinds of machines at home and abroad, and are widely used in many equipments, such as Masa, Hess, Zenith, Tiger, Bessel, Ritu and so on.

Technical data of our molds :

|

Name |

hollow concrete block moulds |

Heat treatment |

Carbonitriding 900-950°C |

| raw material |

special wear-resistant steel |

Hardness |

60-65HRC |

|

Block type |

Hollow block, interlocking block, paver block, kerbstone all can be customized |

HS code |

848060 |

|

lifespan |

100000-120000 times |

Packing |

Wooden +plastic film |

Mold features:

1. The most advanced assembly process.

A: advanced welding technology and de-stress treatment (if there is stress in the mold material, then the processed cavity and core will be deformed in the process of use, which will cause errors in the dimensions, shape and position tolerances in accordance with the drawings. it will make the already qualified products exceed the error value. Will make the already well-matched components become blocked and stuttered. It can't even be used. Therefore, the production of die steel requires a small amount of deformation during heat treatment. Tempering should be carried out after quenching to eliminate the internal stress caused by machining and heat treatment and ensure the normal use of the mold.

B: the press foot clearance related to the machine is 0.3-0.8mm.

C: standard parts and anti-loosening treatment of high strength connection bolts.

D: standardized assembly process for easy replacement of parts.

E: high quality wear resistant steel plate.

F: mold damping function.

G: realizable digital free surface design.

In order to ensure the durability of the mold, our mold goes through the following treatment: carbonitriding heat treatment (60-65HRC).

A: die frame and press foot hardening (60-65HRC).

B: minimum hardening depth 1.2mm.

About our packing:

RFQ:

1.How I can get the quotations?

A. If you have detail drawings of the block you'll need, please send to us to check, we will quote to you as that.

B. If you don't have detail drawings, tell us what type of block you'll need, such as hollow block, solid block etc, take a pic of the block you'll need to us, and tell us the sizes include length*width*thickness by mm.

C. What size of your pallet?

D. What size of your tamper head and the height of your down mold?

E. How your mold will be connected with your machine to work? If you have the connection drawing please provide it.

After getting your information we can quote for you ASAP.

2.How about delivery time:

20-25 work days for common block molds after receiving the deposit from the buyer, and for high-end block molds it needs 30-40 work days.

3.How about transport packing ?

Wooden packing with plastic film or as buyer's requirements!

4.Will the incoming mold be compatible with my machine?

We have been manufacturing many molds for different brands block machines, so we have their related records. So maybe there are some of them are available for you.

In case of need, you can invite an engineer friend to your company to take measurements. Or, we can take a digital image of your mold by sending photos and taking measurements as many of our customers do.

After making sure of the sizing process, the mold we will send to you will be attached to your machine without any problems. Don’t worry about that!

5. How are the payment terms?

In order to complete your order, you will need to pay 50% advance by T/T and the rest must be paid before loading.

6. How to contact with you?

Contact with us by wechat/whatsapp: +86-1330506196 or +86-18960287187 Thanks!

Hot Tags :